New Suggestions For Deciding On Packaging Equipment

Wiki Article

What Are Packaging Machines And Equipment Used For?

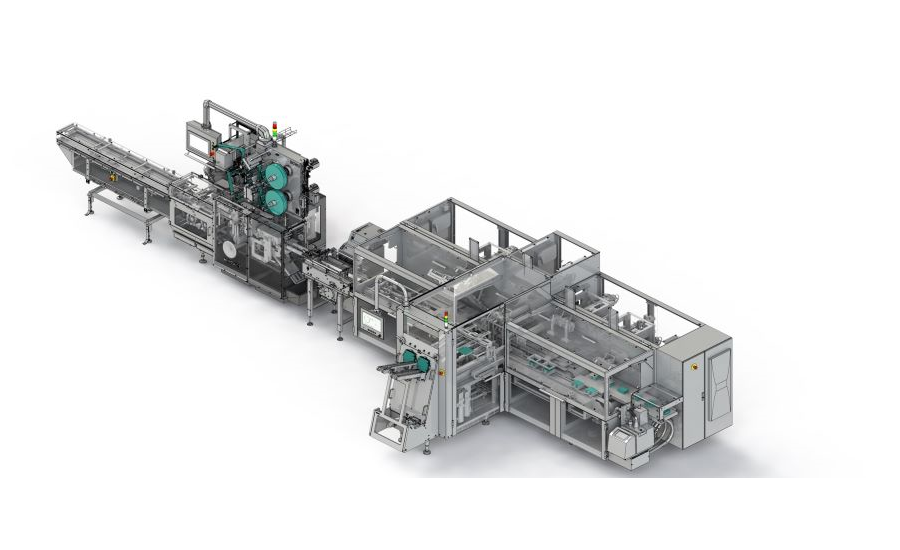

Packaging equipment and machines are instruments that allow you to pack products in large quantities by using automated processes. They can include vacuum packaging machines, filling machines, sealing machines, labeling machines, box forming machines, etc. The advantages of these systems include speed and efficiency that are increased and lower labor costs and improved packaging quality. They can be costly to purchase and to maintain. Additionally, they require some technical expertise to operate properly.

The Fundamental Principles Of Packaging Equipment Are :

Protection- Packaging equipment should protect the product from damage, contamination, and deterioration during storage, transportation, and distribution.Containment- Packaging equipment should contain the product in a secure and stable manner, preventing spillage, leakage, and waste.

Convenience- Products must be accessible and simple to use.

Efficient Processing- It is important to create packaging equipment designed to maximize effectiveness. This will reduce waste, increase production speeds and increase the quality of product.

Cost-effectiveness. Packaging equipment should strike a balance between cost and performance. This will add value to the end user, while also being economically feasible.

Packaging equipment should be easy to operate, clean, and maintain.

Sustainability- Equipment used for packaging should be sustainable. It should reduce the amount of material used to make packaging, reduce waste and have an impact that is minimal on the environmental.

These principles can ensure that packaging equipment provides the performance, protection and ease of use wanted by both the producer and the end-user. Check out the top rated Evolutive cup filler for blog tips..

How Do Vacuum Packaging, Box-Forming And Filling, Cooling, Sealing, Cooling, Marking And Marking Work?

Vacuum packaging is when these machines are used to seal bags using vacuum to prolong shelf life and remove air from the bag. They usually use an air sealer or a vacuum pump to remove air from the bags and seal the bags. Filling machines- These machines can be used to fill containers and bags with product. They can be used to distribute a particular quantity of the product.

Sealing machines- These machines use pressure and heat to seal bags and packages generally made from plastic or other sealable materials. They can be used to seal goods such as medical equipment, food items and electronic equipment.

Labeling machines apply labels to products and packaging. Labels can be applied using heat-sensitive, pressure-sensitive labels or glue to attach the labels to the item.

Box-forming machines- These machines make boxes or cartons out of flat pieces of paperboard. They are able to fold and glue the paperboard in the desired shape and create a box that is ready for packing and shipping.

These equipment and machines utilize different technology to perform their tasks, including sensors control, a variety of mechanical systems. They may also be included in a larger packaging line to increase speed and effectiveness. View the top repeatability aspect for blog examples..

Automated scaling cooling solutions provide an efficient and automated temperature control for a variety applications such as food production, pharmaceutical and biotech manufacturing as well as other industrial processes. These solutions often use advanced technologies such as thermocontrol systems, heat exchangers, and refrigeration units to ensure that the temperature is precisely controlled and products are safe and consistent. Automated and scalable cooling systems will meet the needs of the customers. They are able to be adjusted to meet the changing demands for production. Additionally, they can be integrated with other manufacturing systems to improve efficiency, boost overall productivity and decrease the amount of downtime. Automated, scalable cooling solutions can improve product quality, reduce the time between failures, and improve efficiency in energy use. Read the recommended Enoline for blog advice..

What Are The Main Factors To Consider When Purchasing Packaging Equipment?

Product requirements- The packaging equipment selected will depend on the volume of production that is desired.

Integration- It's crucial to consider the way in which packaging equipment can be integrated into existing manufacturing lines. This includes compatibility with other equipment and the ease of integration.

Maintenance and Support. It is essential to assess the accessibility of maintenance or support services as well as the cost and ease of maintaining equipment.

Cost Include the price of equipment as well as any associated costs such as training, installation maintenance, repair, and training in your overall budget.

Energy efficiency- The effect of the energy consumed on operating expenses can be substantial.

It must be easy to use.

Conformity with industry standards The focus should be given to compliance with standards of the industry, for example, regulations regarding food safety to ensure the equipment is appropriate for the intended purpose.

These aspects are crucial to make sure you take the right decision when purchasing packaging equipment. Have a look at the best Packaging Trends for website recommendations..

What Should You Know Concerning Products For Heat Sealing?

Heat sealing is a process that is used to seal bags or packages made from material that can be heat sealed, like plastic. The process involves the use of the pressure and heat to bond the materials, creating an extremely durable, strong seal.

Seals that are reliable on packages The quality of the heat seal is crucial in ensuring the security of the packaging, since poor sealing can result in leaks, spoilage, or product loss.

Automated packaging methods Heating sealing is often done using automated packaging equipment. This increases effectiveness and reliability.

Robotics/programmable Logical Controllers- Robotics/programmable controllers are commonly used for automated packaging procedures.

Maintenance preventative for packaging equipment It is essential to keep packaging machinery in good working order and keep heat sealing equipment working well.

The cost-effectiveness of packaging materials Heat sealing film can make a significant difference in the overall cost efficiency of packaging. Choosing the right film can help reduce waste, increase production speeds, and increase the quality of the product.

Optimization of packaging It's a way to reduce packaging costs.

The process of packaging- heat seal is only one stage of a bigger package process that also includes the filling, labeling, packing and shipping. Understanding the whole procedure and how heat sealing is integrated into it is important for the success and efficiency of your packing operation. See the top conveyor belts for site info..